Home / Equipment / Lifts / Scissor Alignment Lift / 14K Scissor Alignment Lift

Scissor Alignment Lift

14K Scissor Alignment Lift

Scissor Alignment Lift

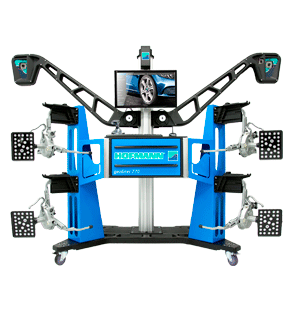

Hofmann® scissor alignment lifts epitomize user-friendliness, affording operators unparalleled ease of operation while concurrently offering enhanced accessibility to alignment adjustment regions. Loading onto these lifts is a seamless task, simplifying the workflow for technicians.

Additionally, these lifts boast a space-efficient design, a testament to engineering ingenuity, which enables the accommodation of up to five scissor lifts within the same operational footprint typically required for 4-Post lifts. This innovative spatial optimization underscores the practicality and resourcefulness of Hofmann® scissor alignment lift systems.

ALI Certified

Flush or Surface Mount

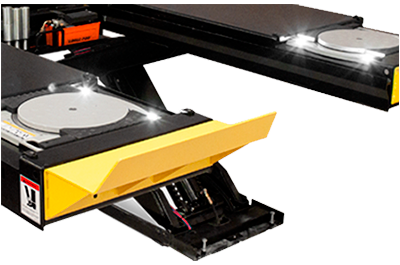

Locked & Lighted

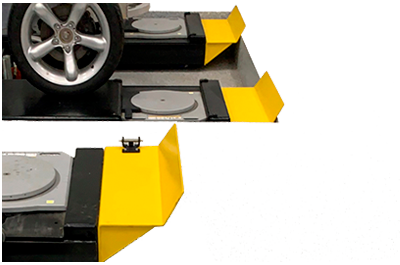

Low-Profile Rolling Jacks

Open Front and Rear Construction

Safety System

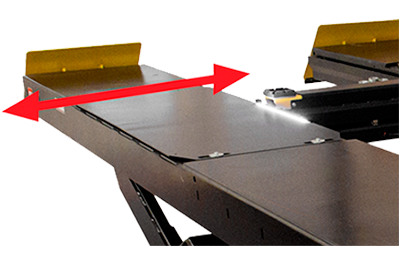

Ultra-Wide Runways

90-140 PSI @ 5-10 CFM

Air Supply Required

Open Front and Rear

Configuration

14,000 lbs. | 6,350 kg

Lifting Capacity

85 seconds

Lifting Time

63" | 160cm

Max. Lifting Height Flush Mount

72" | 183cm

Max. Lifting Height Surface Mount

16'x 33' | 488x1006cm

Minimum Recommended Bay Size WxL

72" | 183cm

Overall Height

93" | 235cm

Overall Width

230V 60Hz 1Ph 20A 2HP / 1.5kW

Power Supply

5,863 lbs. | 2,659 kg

Shipping Weight

| EELR787APKG | STANDARD BAY SURFACE MOUNT |

| EELR788APKG | STANDARD BAY FLUSH MOUNT |

| EELR789APKG | STANDARD BAY SURFACE MOUNT L&L |

| EELR790APKG | STANDARD BAY FLUSH MOUNT L&L |

Downloads

Product Categories

Wheel Aligners

Wheel Aligners

Wheel Balancers

Wheel Balancers

Tire Changers

Tire Changers

Lifts

Lifts