Home / Equipment / Tire Changers

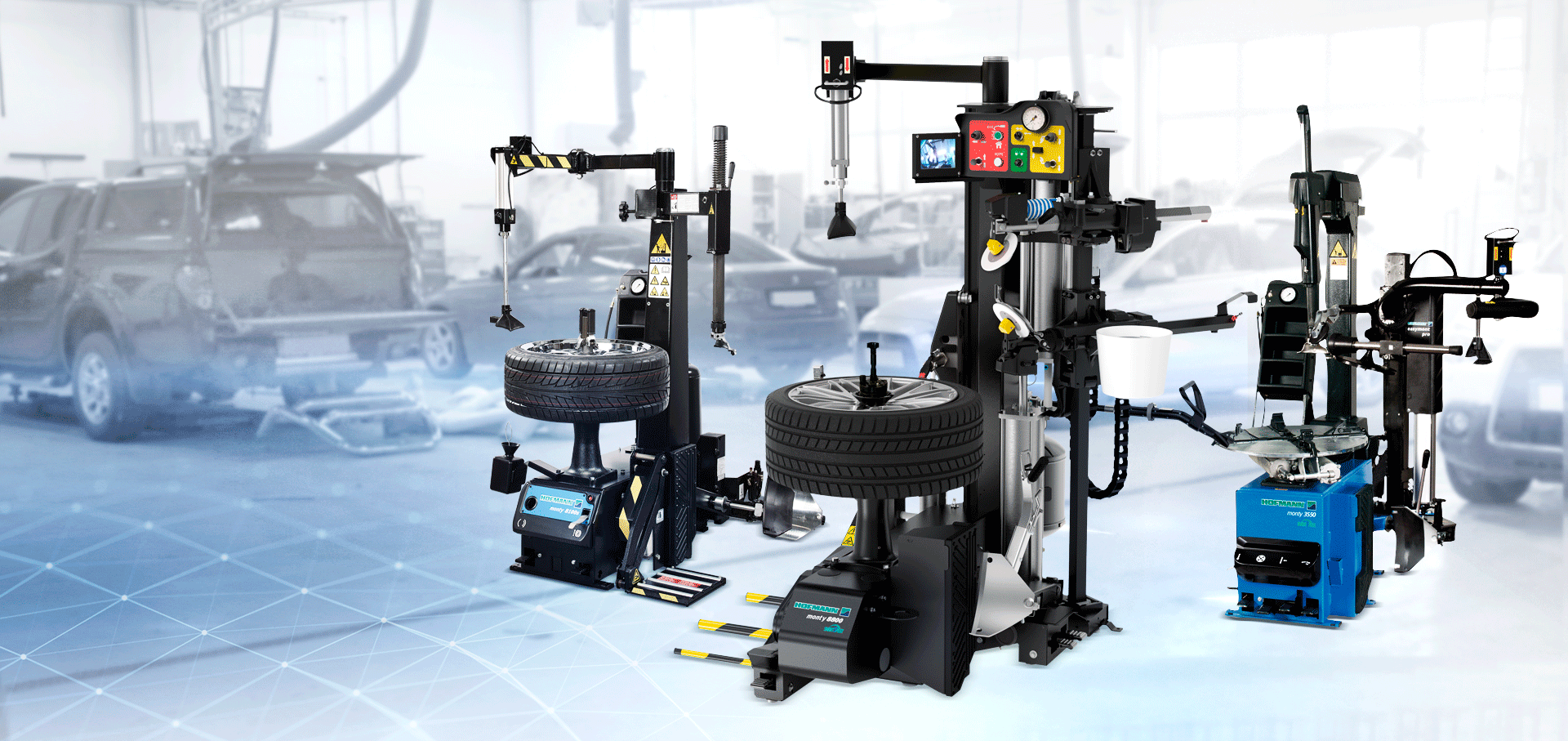

Tire Changers

In the world of automotive repair and maintenance, time and precision are the primary forces driving success. Balancing these two elements is your tire changer, one of the most important tools in your shop. Hofmann® tire changers embody a fusion of unmatched precision, advanced technology, and resilient endurance.

Our line of industry-leading tire changers can service a wide variety of rim widths and tire types, increasing your shop’s productivity with best-in-class versatility, speed, and safety.

Reaping the Benefits of Hofmann Tire Changers

Choosing the right tools and shop equipment can transform your automotive business. When you equip your garage with Hofmann tire changers, you're investing in a suite of benefits that promote increased productivity, enhanced safety, and an elevated profit margin.

Revolutionizing Productivity

In an automotive repair shop, every second counts. Delays in tire changing can lead to longer service times, less satisfied customers, and a decline in overall productivity. Hofmann tire changers are engineered to mitigate these challenges. Each machine we offer is designed to optimize speed without compromising on precision.

Our tire changers enable your technicians to handle high volumes swiftly and with ease. This efficient service results in more satisfied customers and a higher wheel turnover, elevating your shop's productivity to new heights.

Prioritizing Safety

The automotive industry, by its nature, involves potential hazards. It’s important that your shop maintains stringent safety standards to protect your team and your clients' vehicles. With Hofmann tire changers, safety is not an afterthought; it's an integral part of the design and operation.

Each of our machines comes with robust safety features, including a durable bead breaker system and ergonomic operating procedures. These features ensure even the most stubborn tires can be changed with minimal risk of injury or wheel damage. With Hofmann, you can foster a safer working environment and enhance customer trust in your services.

Driving Profitability

By accelerating the tire-changing process, our machines allow you to serve more customers in a shorter time frame, directly impacting your revenue. Moreover, the superior quality and precision of Hofmann tire changers enhances customer satisfaction, promoting repeat business and positive word-of-mouth, thereby driving further growth. With a Hofmann tire changing machine, you're not just boosting your profitability today; you're securing a prosperous future for your business.

Tire Changer Types

Choosing the right tire changer for your shop involves understanding your specific needs and the unique features of different models. Hofmann offers a wide array of tire changers, each type designed to excel in certain areas.

From compact units ideal for small workshops to heavy-duty machines capable of handling the largest truck tires, Hofmann has your tire servicing needs covered.

Leverless Tire Changer

Eliminate the hassle and risks associated with traditional tire changing, with the monty® 8800 and monty® 8700, innovative leverless models from Hofmann. Integrated with the latest center-post design, smartSpeed™ technology, on-floor bead breaker, lower bead camera viewer, and powerMONT™ mounting, these machines are the embodiment of efficiency and safety.

Designed to seamlessly handle a wide range of wheel sizes, the leverless changers are an ideal solution for a high-volume tire shop dealing with diverse tire types, reducing the risk of wheel damage and enhancing productivity.

Tilt-Tower Tire Changer

The Hofmann Tilt-Tower and Rim Clamp Tire Changer models bring an unbeatable combination of robust construction and wide-ranging capabilities. From low-profile to high-performance and run-flat tires, these machines can handle a vast array of wheel and tire assemblies, maximizing your shop's wheel service scope.

Swing Arm Tire Changer

The Hofmann Swing Arm Tire Changer models offer a classic design that maximizes productivity with easy-to-use features. The mounting arm swings to the side so that the machine can be installed near a wall, optimizing your tire shop space.

Heavy Duty Tire Changer

When heavyweight tires are part of your everyday operations, the Hofmann Heavy-Duty models, like the monty® 5800B and monty® 4400, come into their own. Their robust chuck designs and reinforced frames can handle wheels weighing up to 1500kg, making them an ideal solution for heavy-duty tires.

The control units allow simultaneous control of two operations, enhancing operational efficiency. These powerhouses are especially beneficial for larger workshops that frequently service trucks and larger commercial vehicles.

FAQs: Unraveling Your Tire Changer Queries

What should I consider when purchasing a tire changer?

When purchasing a tire changer, consider the type and size of tires you most commonly work with, the volume of work your tire shop handles, and the level of experience your technicians possess.

Also, look for advanced features that can make operations more efficient, such as bead breaking technology or leverless designs. Durability, ease of use, and the level of support provided by the manufacturer should also be key considerations.

What types of wheels can I service?

With a Hofmann tire machine, you can service a wide array of wheels. From standard passenger car and SUV wheels to large truck wheels, our machines can handle them all. Specific models, like a heavy duty tire changer or rim clamp tire changer, may be better suited to certain wheel sizes and types, so it's always best to check the specifications of the model you're interested in.

What do UHP and RFT mean?

UHP stands for Ultra High Performance, referring to tires that are designed for high-speed vehicles and offer exceptional handling and braking performance. RFT stands for Run Flat Tires, which are designed to resist the effects of deflation when punctured, allowing the vehicle to continue to be driven at reduced speeds and for limited distances.

What should training for tire changers involve?

Training for using tire changers involves learning about the different models, understanding their unique features, and gaining hands-on experience.

Subjects that should be covered in-depth while training include:

- Understanding the technical specifications and functionalities of each model.

- Familiarization with the control panel and learning about various settings and adjustments.

- Hands-on demonstrations for mounting and dismounting different types of tires, including run-flat and UHP tires.

- Best practices for ensuring safety during tire-changing procedures.

- Troubleshooting common problems and performing basic maintenance tasks.

What distinguishes Hofmann tire changers from other brands on the market?

Whether you're looking for a tire changer, wheel balancer, or automotive lifts, Hofmann stands out from other brands on the market due to innovative design, superior quality, and commitment to enhancing shop productivity.

Here are some key differentiating factors:

- Innovative Features: Hofmann tire changers are equipped with features like smartSpeed™ technology, integrated wheel lift, and on-floor bead breaker that significantly enhance efficiency and productivity.

- Quality and Durability: Built with high-end components and rigorous testing, Hofmann tire changer machines are designed for longevity and consistent performance, even in high-volume settings.

- Wide Range of Options: Hofmann offers a comprehensive lineup of tire-changing machines designed to meet the unique needs of different shops, whether they service passenger vehicles, trucks, or high-performance sports cars.

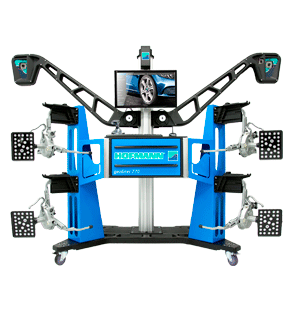

Wheel Aligners

Wheel Aligners

Wheel Balancers

Wheel Balancers

Tire Changers

Tire Changers

Lifts

Lifts