Home / Equipment / MOT and Emissions / Upgrades and Equipment / Brake Tester

Brake Tester

Class I, II, III, IV, VL, VII

Hofmann® Brake Tester: Precision, Efficiency, and 10-Year Roller Warranty!

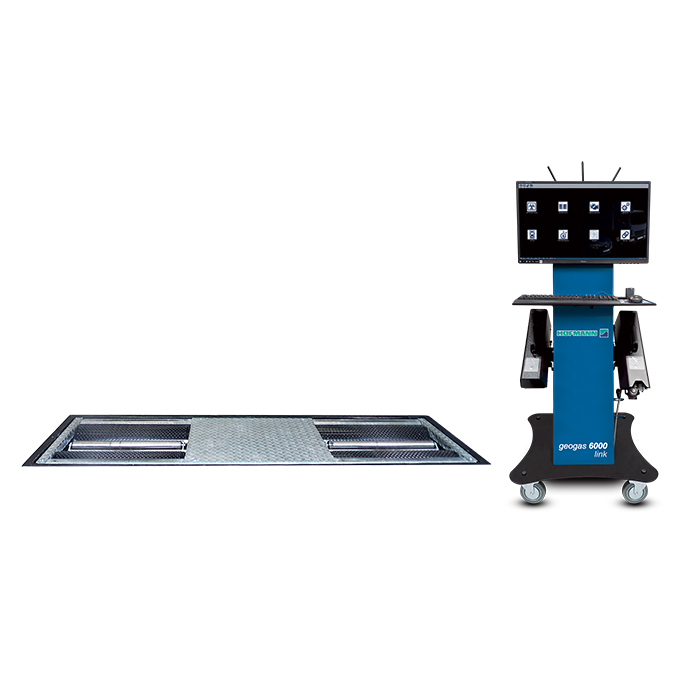

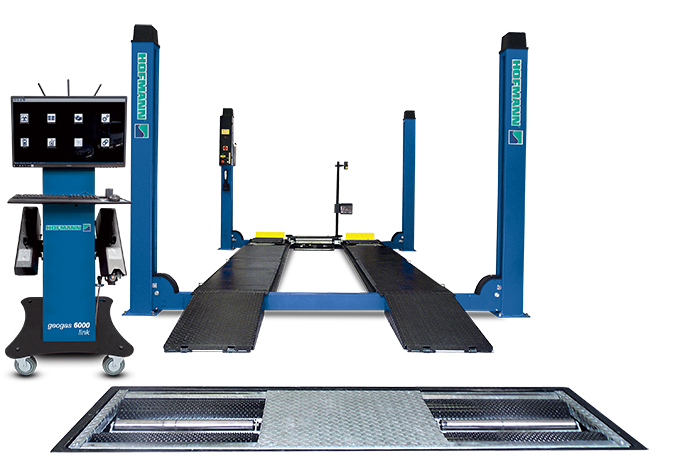

Ascend to new heights of brake testing competence with the latest brake tester system from Hofmann®, which offers an exceptional combination of precision, reliability, and 10 years of guaranteed roller surface durability. These systems incorporate a state-of-the-art solid-state motor control system, contributing to an unparallelled level of sophistication. They serve as stand-alone units or can be seamlessly integrated into the geogas 6000 links, providing an optional brake tester extension for the gas analyser unit. Whether your requirements demand unrivalled precision in brake tests or a comprehensive solution for automated test lanes, Hofmann® presents pioneering technology and a decade-long roller warranty to instill confidence.

FEATURES

Two Chassis Options:

The 700mm rollers are designed for class I, II, III, and IV vehicle testing, with a drive-over capacity of up to 4T (800Kgf brake force). The 1000mm rollers, meanwhile, offer compatibility with class I, II, III, IV, VL, and VII testing (class I and II require an optional adaptor plate) and can handle a drive-over capacity of up to 6000KG (1250Kgf brake force).

Robust Construction:

The chassis is constructed from fully galvanised steel, ensuring long-lasting durability, and roller covers are a standard feature, simplifying vehicle exit.

Dimpled Roller Surface:

The brake tester's dimpled roller surface provides protection to tyres while offering a coefficient similar to the road surface, ensuring precise and consistent results in both wet and dry conditions.

User-Friendly Interface:

Designed for simplicity, the graphical user interface mirrors the familiar meter displays of older analog units while incorporating modern technology, incorporating the latest advancements in brake testing technology, functions, and procedures.

Weighing System:

The weighing system supports wheel-based weighing, standard on automated test lanes and optional on non-ATL setups. Additionally, it includes an auto-sensing 4×4 option as standard.

Comprehensive Package:

Hofmann® brake testers are supplied with a monitor, laser printer, and a database for storing test results. After completing the brake test, results can be reviewed on the display with error highlighting, printed with failure reasons if applicable, and stored in the database for future retrieval.

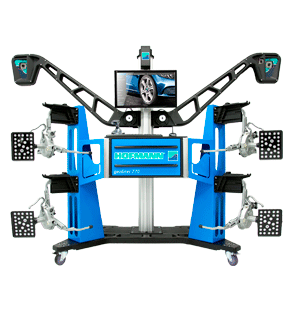

Wheel Aligners

Wheel Aligners

MOT and Emissions

MOT and Emissions

Wheel Balancers

Wheel Balancers

Tyre Changers

Tyre Changers

Lifts

Lifts