Eliminating the need for manual input, this intelligent machine automatically detects wheel dimensions and selects the appropriate balancing mode, weight type, and weight position. This automation accelerates the balancing cycle, reduces operational errors, and enhances efficiency.

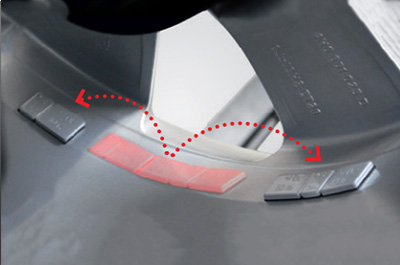

AUTOMATIC SPOKE DETECTION

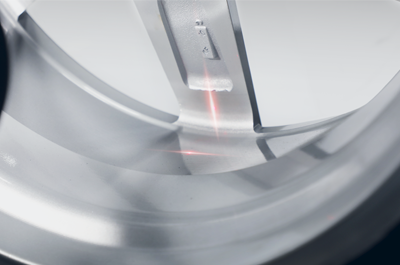

Leveraging a laser scanner, this advanced system autonomously identifies the precise number and position of rim spokes. Consequently, the system provides guidance for optimal weight placement behind the spokes, enabling the use of split weights for precise balancing.

Streamlining weight placement, this precision-focused system eliminates the guesswork. It employs a laser to precisely indicate the exact location for weight application, ensuring meticulous balancing and accurate results.

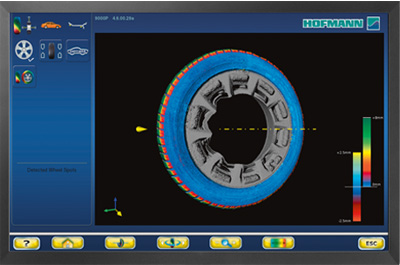

Leveraging cutting-edge technology comprising a high-resolution camera and laser-based sensors, this innovative feature facilitates detailed analysis of the tyre's sidewall. It accurately assesses parameters such as depth, wear, and surface irregularities, providing valuable information presented in a user-friendly format.

Employing sophisticated techniques, this process optimises the assembly of the tyre onto the rim, reducing the need for excessive weight addition. By achieving a more balanced distribution, it enhances overall performance and minimises potential vibrations.

OPTILINE™ WHEEL SET OPTIMISATION

Utilising a pre-established set of criteria, OptiLine intelligently identifies and recommends the most favourable position for each wheel, effectively resolving any concerns associated with pull or vibration.

Utilising advanced electromechanical technology, this balancer incorporates a power clamping device that consistently and reliably secures the wheel with a constant force. This ensures exceptional accuracy and repeatable results every time.

Comprehensive reports can be effortlessly generated through the local network or saved as PDF files onto an external flash drive. This convenient feature enables easy access to detailed information for reference or documentation purposes that can easily be shared with customers.

Engineered for optimal performance, this feature intelligently adjusts the number of revolutions according to each wheel's specifications. Operating at maximum speed, it effectively reduces cycle time, delivering swift and efficient results.

A vast array of measurement points are meticulously captured with an impressive resolution of 0.004″ (0.1 mm). This data is utilised to model a 3D of the tyre and wheel assembly, enabling a comprehensive assessment of its uniformity. The resulting analysis determines the radial runout, presenting peak-to-peak measurements spanning from the first to the third harmonic.

SEMI-AUTOMATIC DATA ENTRY

Equipped with a user-friendly gauge arm, this system facilitates data entry with easyALU™ assisted rim measurement technology. Technicians simply touch the rim with the gauge arm, and the system automatically enters the rim dimensions and selects the appropriate weight-balancing mode.

This intelligent system utilises sonar sensors to automatically detect the rim width, eliminating the need for manual input and reducing the possibility of errors. By streamlining the process, it enhances efficiency and accuracy.

This feature ensures accurate balancing and discreet weight concealment behind spokes, maintaining wheel aesthetic appeal and visual presentation.

By simply touching the screen, users can prompt the system to automatically rotate the wheel to the precise position for weight application. This convenient feature streamlines the process and enhances operational efficiency.

Boasting a rapid and intuitive interface, this system incorporates a large touchscreen display with easy-to-read large digits. Additionally, coloured weight position indicators enhance speed, ease of use, and overall ergonomics, facilitating daily operations.

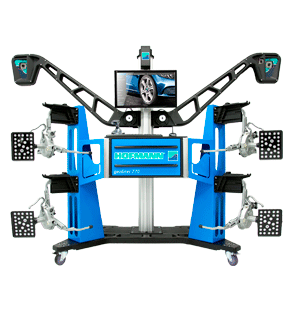

Wheel Aligners

Wheel Aligners

Wheel Balancers

Wheel Balancers

Tyre Changers

Tyre Changers